Power Calibration with Copper Mountain Technologies VNAs - Quick Start Guide

September 1, 2020Quick Start Guide

Performing amplifier, mixer, or other sensitive DUT measurements accurately and correctly depends on proper setup and appropriate calibration. Power calibration using power sensors at the DUT calibration plane ensures precise results.

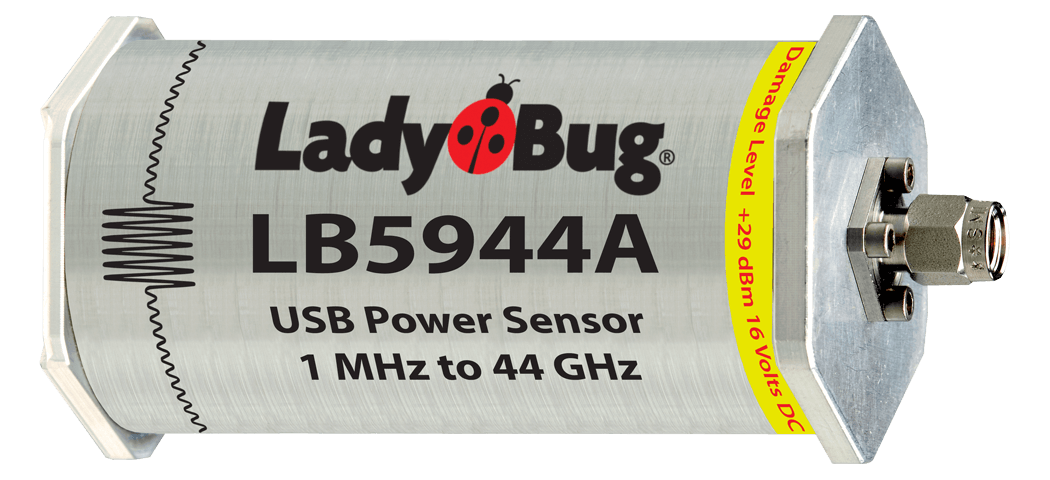

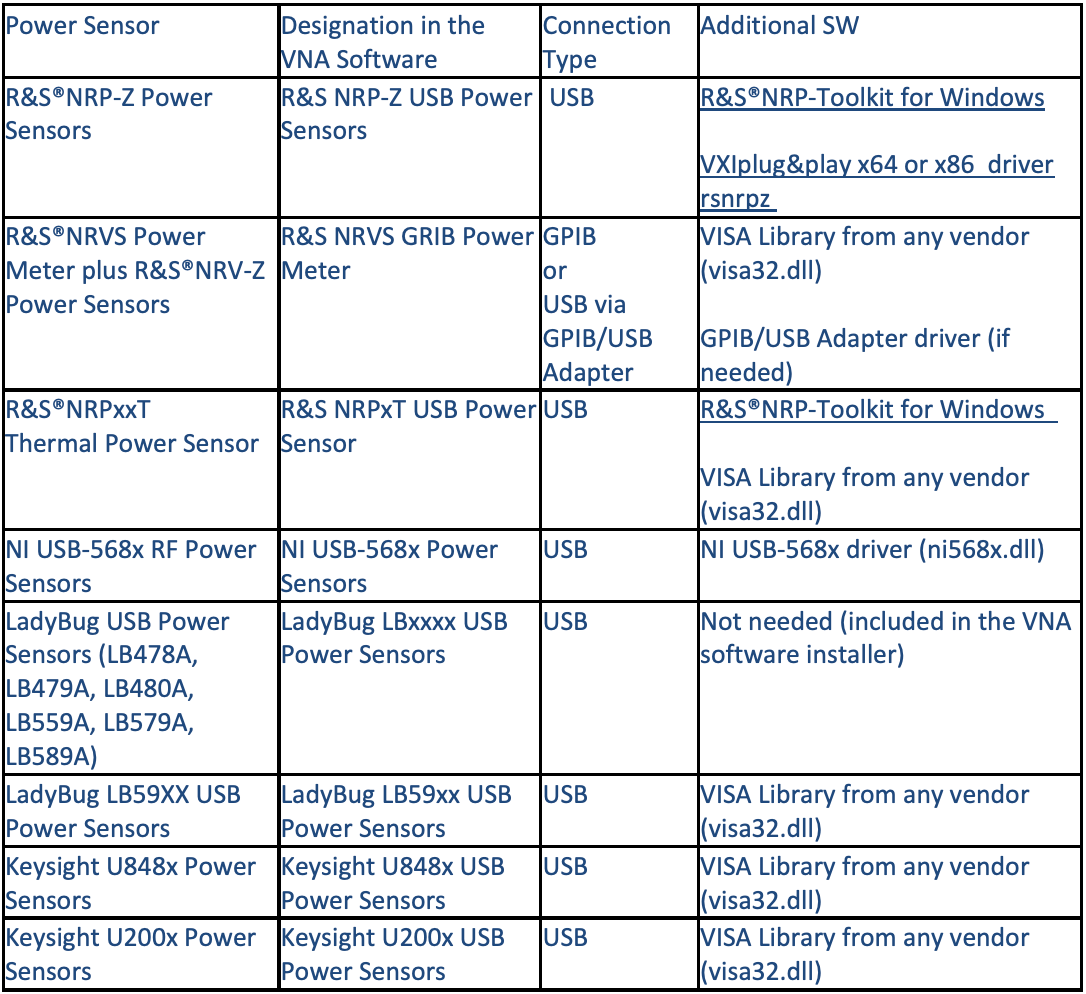

Copper Mountain Technologies VNAs support the following external power sensors:

Selecting Appropriate Power Sensor

To select the power meter: System > Misc Setup > Power Meter

NI USB-568x requires Com port setting. R&S NRVS power meter requires GPIB address settings. These settings are configured after choosing the power meter.

Checking Power Sensor Connection

To check the power meter connection: System > Misc Setup > Check Connection

Power Calibration

After connecting the sensor to one of the ports: Calibration > Power Calibration > Select Port

To zero power meter: Calibration > Power Calibration > Power Sensor Zero Correction

Power meter sensor can be connected to the port, as during zero setting the output signal of the port is turned off.

To execute power calibration: Calibration > Power Calibration > Take Cal Sweep

After the power calibration is complete, power correction automatically turns on.

To enable/disable power correction: Calibration > Power Calibration > Correction

Loss Compensation Table

The loss compensation function allows the user to apply compensation for unwanted losses produced between the power meter and the calibrated port in the process of power calibration. To have the losses compensated the Loss Compensation function needs to be enabled and table would have to be filled out. Linear interpolation will be applied to the losses in the intermediary frequency points. The loss compensation table is defined for each port individually.

Calibration > Power Calibration > Loss Compen – ON

To enable the loss compensation function: Calibration > Power Calibration > Loss Compen > Compensation

To add a new row to the loss compensation table: Calibration > Power Calibration > Loss Compen > Add

To delete highlighted row: Calibration > Power Calibration > Loss Compen > Delete

To clear the table: Calibration > Power Calibration > Loss Compen > Clear Loss Table

To save the table into a *.lct file: Calibration > Power Calibration > Loss Compen > Export Loss Table

To open the table from a *.lct file from the hard: Calibration > Power Calibration > Loss Compen > Import Loss Table

Related Post

Calibration Types and Considerations

April 19, 2018

One of the most frequently asked questions we receive at Copper Mountain Technologies’ sales and support departments goes something like this: “What about calibration?” It’s an unfortunate reality that in the English language, Calibration has two completely distinct definitions. The first relates to checking out the instrument periodically to make sure it is operating within its specifications. “Performance test” is the procedure by which the analyzer performance is verified, typically annually. The second meaning is to do with Measurement or User calibration, a collection of techniques by which measurement accuracy is maximized and made to exclude elements of the system from those measurements (such as cables, adapters and the like). In this application note, we discuss both meanings of calibration as related to Copper Mountain Technologies’ Vector Network Analyzers (VNAs). First, we describe Annual Calibration and then later we discuss measurement calibration.

Using a Databased SOLT Calibration Kit

April 19, 2018

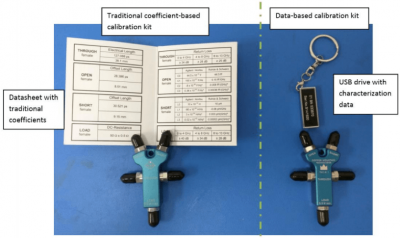

Copper Mountain Technologies produces lab-grade VNAs with outstanding measurement accuracy. As with every VNA, performing a good calibration is necessary for maximizing the accuracy of VNA measurement results, for de-embedding the effects of imperfect cables and components in the fixture, and for moving the reference plane to the DUT interfaces. There are several approaches for determination and application of VNA measurement corrections, including port extension (a relatively crude, approximate method), fixture de-embedding (with accuracy depending on correctness of the model), and calibrating with a calibration kit (a high accuracy approach). Generally, there are two broad categories of calibration kit types: traditional mechanical kits and automatic/electronic calibration modules. Within mechanical kits, there are two types of kits: those with standard “polynomial” coefficients and those with full S-parameter characterization data, also known as databased kits. This application note introduces databased calibration kits, explains why their use is growing in popularity, and describes how they can be used with Copper Mountain Technologies VNAs.

Comments (31)