What Makes a Good VNA?

February 14, 2018Introduction

Everyone knows that a good VNA should have both excellent hardware performance and an easy to use software interface with useful post-processing capabilities. There are numerous VNAs in the market with different performance levels; some of them are economy grade, and others are truly laboratory test grade. What separates the two?

This white paper will focus on specific components and design solutions that maximize the performance of a VNA, in part by comparing modern VNAs with designs of the last century.

VNA Performance Specifications

Before discussing the individual components that make for a good VNA, let’s take a look at the key performance specs of the instrument. Those include:

Frequency range: Determines the frequency range of the measurement results you can obtain.

Frequency setting resolution: The smallest frequency step you can get from the instrument. It limits the resolution of all measurements.

Measurement accuracy: In some sense the bottom line. Relates to measurement uncertainty of both magnitude and phase.

Output power range: The power levels you can have at the test port. Some DUTs have different responses when the input power level varies; these will be designed to operate within a range of input powers, or at a particular input power.

Power resolution: How finely the output power can be adjusted; better power resolution allows for more accurate output power settings.

Harmonic distortion & non-harmonic spurious at output port: Amount of undesired signals present at the test port. Low distortion can provide more accurate results, especially when measuring DUT distortion or harmonics.

Measurement speed: Speed of measurement, typically per measurement point; can have large impact on total cycle time when the VNA stimulus settings leads to a long sweep time.

Components of an Exceptional VNA

To produce a VNA with outstanding specifications, many individual elements need to be chosen wisely and optimized for the application. Let’s look at some of the most important components.

-

Directional coupler

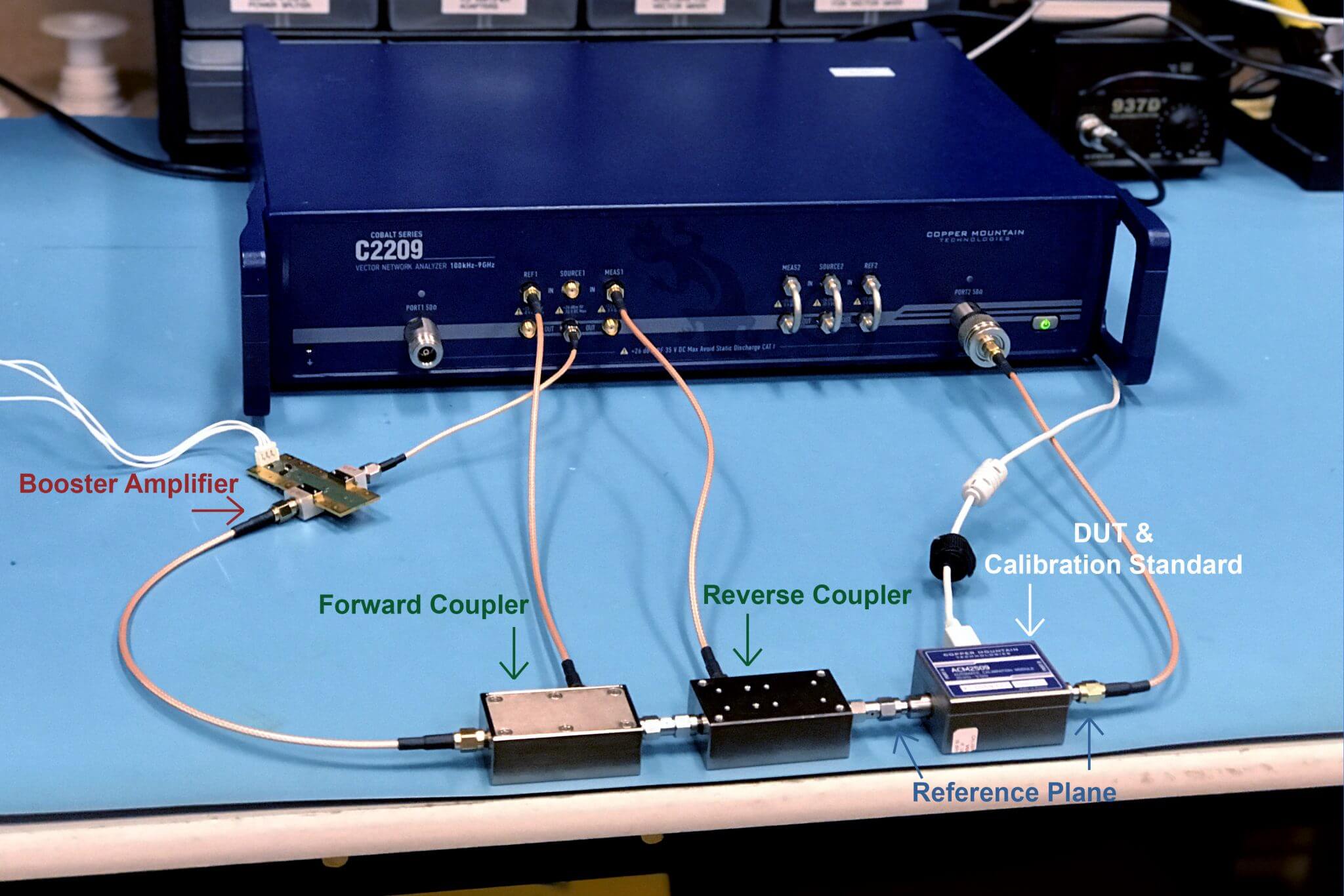

First, we will consider the directional coupler. The coupler is responsible for creating a reference signal proportional to the output incident signal, so that the measurement result can be accurately shown as a ratio of power transmitted or reflected (S-parameter). A well-built directional coupler can lower the VNA’s noise floor, which results in increased dynamic range. A stable coupler can also maintain its characteristics over temperature, allowing users to perform calibration less frequently while maintaining accuracy of the test result.

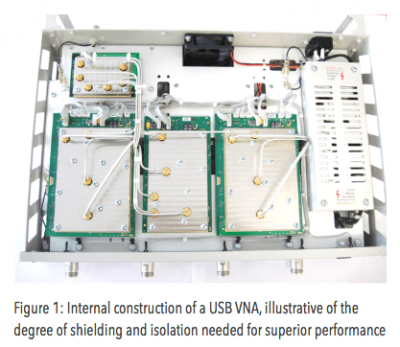

Building a good directional coupler starts from selection of good components with stable performance over frequency and outstanding RF performance characteristics. In addition to the individual components, internal and external shielding of the coupler is important as well. Superior shielding can minimize cross talk between different RF paths and EMI among modules. This helps the directional coupler provide a pure output that is less prone to interference from its surrounding environment.

Not only does shielding constrain the electromagnetic waves’ propagation, it also provides thermal mass to stabilize temperatures within the coupler. Internal temperature stability is critical for accuracy because, to some extent, all components in the design will exhibit some degree of temperature dependence.

-

Mixer

The mixer is another very important component inside the VNA. Modern VNAs normally use a mixer instead of a sampler, which older VNAs used because of its simpler design and lower cost. A good mixer contributes to a low noise floor and minimizes both unwanted spurious responses and trace noise. To make a good mixer, in addition to selecting high quality components, excellent shielding is necessary to minimize crosstalk and enable production of a high dynamic-range instrument. Providing a common and coherent LO to all the mixers is necessary to improve measurement trace noise as well as to reduce LO phase noise.

-

Source

The VNA source is not only an essential module, but also a major contributor to the total instrument cost. In principal, the source can be either external or integrated. The advantage of using an external source is improved purity of the signal, because the source can be more completely shielded and isolated from other modules. The advantages of using an integrated source include high sweeping speed, enabling a more compact measurement solution, reduction of cost, and shorter and simpler interconnections between the source and other components. Through proper design of the source and its shielding, a sufficiently clean internal source can be obtained without the drawbacks of using an external source.

Automatic-loop-control (ALC) is another important aspect of the VNA source that provides the ability to vary the output power level. Old VNAs may use an analog input for the ALC, while modern VNAs use only digital controls. Digital control provides modern VNAs the ability to generate very accurate power levels as well as to supply a wider range of output power settings. Most modern VNAs also have a power flatness specification which shows the consistency of output power levels across frequency. Outstanding flatness can be achieved through application of digital ALC corrections determined at the time of factory calibration.

-

Attenuator

Most modern VNAs also incorporate a step attenuator between the reference coupler and the test coupler,

so that a greater power output range can be achieved compared to purely ALC-based circuits. Adding a step attenuator not only widens the output power range, but also provides a good match to the test port. The attenuator will reduce the difference between the power source match and ratio source match, thereby improving the output port match. Another appealing improvement the step attenuator brings relates to the noise level of signals. The attenuator allows for a large signal in the reference channel even when a small signal is needed at the test port, which will contribute to generation of a low noise signal at the test port.

-

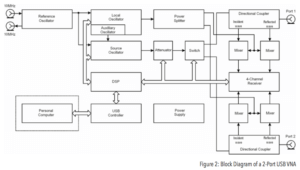

Digital Processing

After the RF components and modules have done their job, signals arrive at the digital section of the VNA for sampling and processing. Because of the high degree of integration and synchronization among the various RF components of the VNA, a dedicated digital processing section is critical for optimization of the system’s performance.

The speed and precision of the digital processors of the VNA are critical for overall VNA performance, influencing such specifications as noise floor, maximum measurement speed, and measurement latency. Modern VNAs incorporate advanced FPGAs, high speed DSP chips, or both to accomplish the digital signal processing needed to produce the raw measurement data at a high speed.

The raw measurement data must also be transmitted expeditiously to the application processor, be it an internal processor or and external processor in the case of a modular VNA. For example, high speed low latency interfaces such as Ethernet and USB are often used in modern VNAs to shuttle raw results to the application layer.

-

Software & Interfaces

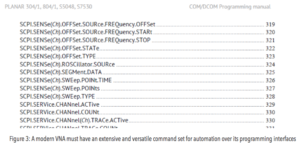

Last but not least, a modern VNA will have user and programming interfaces with the post-processing feature set needed for analysis of results and automation of tests. The graphical user interface typically will be a stand-alone application running in a modern operating system, providing advantages to the user of a stable platform, ease of data transfer to other applications on the same machine, and built-in automation interfaces to other machines and networks.

In addition to the graphical user interface, a great VNA will include one or more interfaces allowing for

automation of measurements and data transfer of measurement results. This is especially critical in production environments where the same tests are being performed repeatedly and consistency is a key for quality management. Interfaces such as SCPI, VXI-11, COM/DCOM, and TCP socket are popular options for the automation interface.

Conclusion

Building a great VNA starts from selection of outstanding building blocks, including RF components like mixers, attenuators, oscillators. An exceptional design will combine these into functional units such as directional couplers, RF sources, and digital processing engines having great performance. It is the sum of all these elements, in combination with versatile and feature-rich interfaces, that makes for a lab-grade, world-class VNA.

Comments (0)